Manufacturing is one industry that has embraced cloud speedily and profitably. The global IaaS industrial cloud market was valued at close to $5.6 billion in 2015, and the global PaaS industrial cloud market at close to $3.8 billion. Concurrently, there has been a lot of excitement and hype about Industry 4.0 and the Industrial Internet of Things.

Cloud-based systems have proven quicker to roll out and easier to customise, and are dramatically saving on costs. But the real story is that cloud plays directly to two of manufacturing’s sweet spots: keeping production running, and accelerating New Product Development.

Manufacturing companies thrive or fail on their ability to guarantee uptime – the so-called “five nines” is their mantra: 99.999% online uptime – making sure systems and processes work together to provide this. Uptime isn’t optional, it’s mission-critical.

There are numerous advantages to the sector of using cloud services, which include the following:

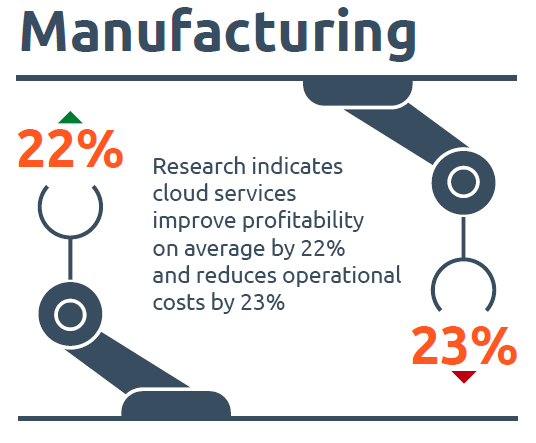

The impact on profitability in manufacturing is significant. Oracle states that cloud computing demonstrates an average improvement of 22% in profitability and an average reduction in costs (attributed to optimised manufacturing operations and planning processes) of 23%.

Visibility and collaboration are two things which are central to ensuring manufacturing efficiency, as it is a sector that really cannot afford to have information silos. End-to-end, integrated solutions allow manufacturing companies to collaborate, connect, and share solutions with others in the organisation and across the supply chain. This enables processes and flows that span the extended enterprise, partners, and customers. Complete visibility encourages more insightful decision-making and enhances end-to-end business flows, as real-time views offer visibility into work orders. Collaboration is also aided by using integrated social solutions to resolve shop floor issues.

Energy consumption data, production data, and direct sensor data (perhaps enabled by the Internet of Things), provides great value for manufacturers. This data can be used to define actionable insight that populates the dashboards of shop-floor management and decision makers so they can – in real-time – chart production line efficiency and the course of facility improvements. Critical information alerts – for example, when a production line is down – can be sent from cloud-based services as e-mails and push notifications to mobile devices.

Given that manufacturers often run widely dispersed facilities, cloud is proving invaluable for monitoring machines remotely. Gathering all sorts of data from the shop-floor enables the implementation of high-performance condition monitoring. This is invaluable for remote support and service, and feeds directly into the predictive maintenance of expensive, bespoke assets. Using pattern recognition for detecting irregularities in the data can improve process reliability.

NPD is critical to the long-term survival of any manufacturer. Historically, IT has been seen as an inhibitor to NPD, slowing it down. Cloud has in effect turned this on its head, reducing both product development cycles and cost. Nowhere are cloud’s benefits foregrounded better than in testing and development.

Cloud enables manufacturers to run large-scale product development simulations without having to invest in (and maintain) the physical resources needed for testing. The cloud provides the scalability to meet the peak compute and storage needs, and manufacturers only have to pay when they use those resources.

Cloud storage solutions traditionally offer reduced downtime in the event of a data loss, and allow for easier locating and restoring of data. Using the cloud backup also enables increased scalability, as manufacturers can manipulate storage at any time.

Manufacturing is seeing some of the most successful and exciting uses of cloud. The power of cloud databases and next-generation analytics are helping the leading manufacturers harness big data to leverage a huge competitive advantage.

At DSP we know that it’s the responsibility of cloud providers to not only deliver infrastructure and applications, but provide the managed services necessary to keep them running efficiently. Maintaining an in-house IT team can be difficult and expensive, and ultimately can compromise quality and security. DSP offer a host of services and an army of specialists for you to draw on when necessary, giving you a virtual IT department dedicated to meeting your specific needs and costs effectively. Find out more about our IT services for manufacturing.

DSP is a Data Management and Cloud Platform MSP that delivers enterprise grade support & consulting services for Oracle, Microsoft and Multi-Cloud technologies.

.png?width=250&height=99&name=Partner-logos-rectangle-colour-Nov21%20(2).png)